CWT Compact S2 Installation & Maintenance Manual

Visible paper dust should be blown off regularly (at least once per year), especially from the black mark and paper-out opto-sensors.

| Caution: Deposits accumulating on the row of heating points on the print head will negatively affect the thermal head’s cooling which might damage or destroy the print head. |

The transportation rolls must be cleaned regularly. The frequency of cleaning depends on factors such as paper quality, the type of pre-printing on the tickets, and the degree of air pollution.

1.Pull the metal lever to release the Ticket Presenter

2.Moisten a lint free piece of cloth (non-woven textile is recommended) or a piece of paper with platen cleaner solvent usually available on the market.

3.Wipe off the presenter feed rolls A and B

To clean the printer, disconnect and dismount the printer from the module and from its casing. Open the printer using the leaver on the bottom of the printer. See Print head for detailed figures

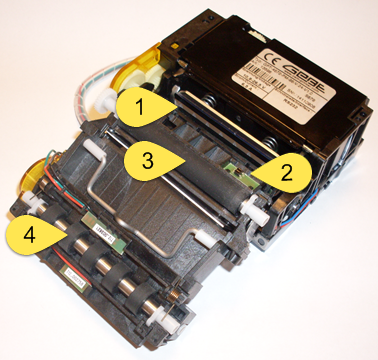

47, Cleaning points inside the printer

4.Use an air blower to remove dirt and small paper particles inside the printer.

5.Check that the black mark/paper out (2) sensor is clean.

6.Moisten a lint free piece of cloth (non-woven textile is recommended) or a piece of paper with platen cleaner solvent usually available on the market.

7.Wipe off the presenter feed rolls (3 and 4) while rotating them. Ensure that there are no paper particles left.

8.Wipe off the row of heating points (1) on the print head using isopropyl alcohol.

9.Re-mount the printer in its casing and on the mounting plate.