CWT Compact S2 Installation & Maintenance Manual

The task of the escrow is to store the inserted coins until the customer accepts or cancels the purchase. Accepted coins are guided into the coin box. Cancelling the purchase empties the coins into the coin return cup. The volume of the escrow is approximately 0.35 l, equal to about 120 coins.

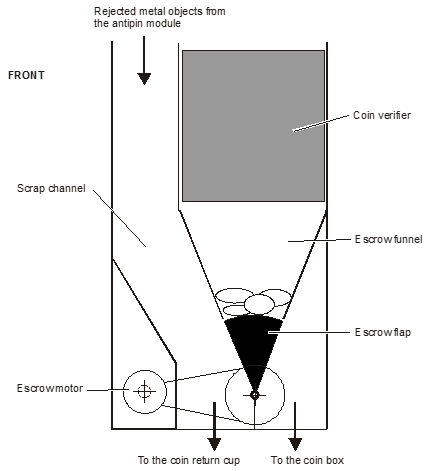

Figure 8, Escrow in home position.

The figure above shows the coin unit as seen from the terminal’s right side.

To the left is the scrap channel through which any objects rejected by the anti-pin module or the coin verifier will fall into the coin return cup.

Below the coin verifier is the escrow that consist of a funnel, a flap and a DC motor (escrow motor).

The flap can be rotated to the left or right by the motor via a toothed belt and a pulley attached to the flap. The pulley has a small permanent magnet mounted close to its outer edge. There is a printed circuit board, named coin handling board, mounted on the left side of the coin system module (not shown in the above figure). This board has three Hall- effect sensors that detect the position of the permanent magnet, and thus the position of the pulley and the flap.

The figure above shows the escrow flap in home position, that is, the position it has until the customer either accepts or cancels the purchase. Any inserted coins remain inside the escrow funnel.

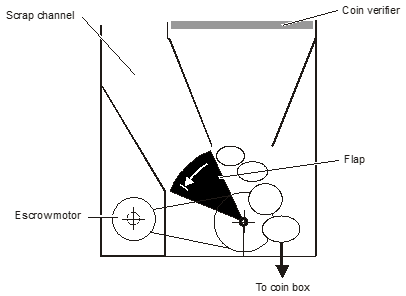

In the figure below the customer has accepted the purchase and the escrow motor have turned the flap to the Accepted Purchase position. The coins fall into the coin box.

Figure 9, Escrow in Accepted Purchase position.

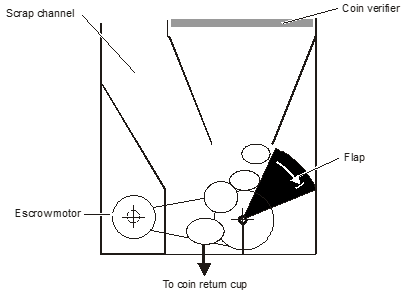

In the next figure, the customer has cancelled the purchase and the escrow motor has turned the flap to the Cancelled Purchase position. The coins fall into the coin return cup.

Figure 10, Escrow in Cancelled Purchase position.